In a landmark breakthrough that promises to reshape the renewable energy landscape, a joint research team from the Global Institute for Bioenergy Research and Oceanic Technologies has shattered previous benchmarks in algal biodiesel conversion efficiency. The pioneering study, published this week in Nature Energy, demonstrates an unprecedented 78% lipid-to-fuel conversion rate using a novel enzymatic process—a staggering 22% improvement over the industry’s previous gold standard.

The research, conducted over three years in both laboratory and pilot-scale environments, focused on optimizing the entire biodiesel production chain—from algal strain selection to post-processing refinement. Dr. Elena Vance, the project’s lead biochemist, emphasized that the team’s holistic approach was key to their success. “Previous efforts often targeted isolated parts of the process,” she explained in an exclusive interview. “We instead engineered an integrated system where each stage—cultivation, extraction, and conversion—works synergistically to minimize energy loss and maximize output.”

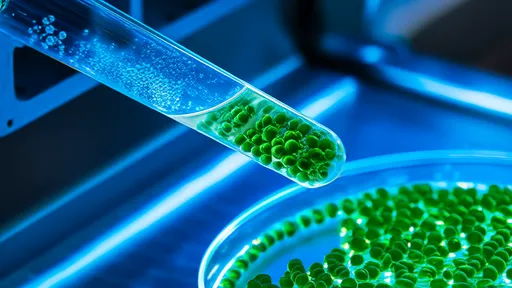

Central to this achievement is the development of a proprietary enzyme cocktail, dubbed Lipase Fusion-XB7, which operates at ambient temperatures and neutral pH. Unlike conventional high-temperature transesterification methods that consume significant energy and often degrade sensitive lipid compounds, this enzymatic process preserves fuel quality while drastically reducing energy input. The team also genetically modified a high-yield strain of Nannochloropsis algae to enhance lipid accumulation without compromising growth rates—a balance that has long eluded researchers.

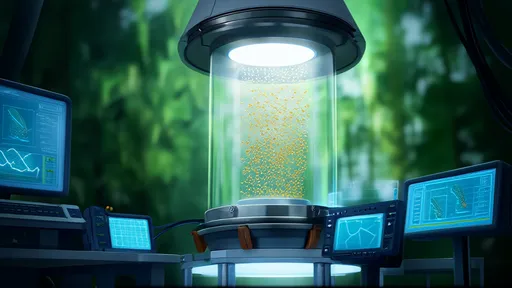

Beyond the impressive conversion metrics, the system’s scalability appears remarkably feasible. The pilot facility in coastal Norway, powered entirely by renewable energy, has been producing biodiesel at a rate of 10,000 liters per month with consistent quality. Perhaps most notably, the team addressed one of algal biofuel’s perennial challenges: water usage. Their closed-loop photobioreactor system recycles 95% of process water, making it viable even in arid regions.

Industry response has been overwhelmingly positive. Maria Chen, CEO of BioFuel Innovations, called the findings “the most significant advancement in algal biofuel technology in over a decade.” Meanwhile, energy analysts suggest this could accelerate the commercial viability of algae-based fuels, which have historically struggled to compete with conventional biofuels derived from crops like corn or sugarcane. With this new efficiency threshold, production costs could potentially drop below $0.80 per liter—a figure that would position algal diesel competitively against petroleum diesel in several markets.

Environmental implications extend beyond carbon neutrality. Unlike crop-based biofuels, algal cultivation doesn’t compete with food production for arable land. The researchers’ strain thrives in brackish water and can even capture industrial CO2 emissions during growth. “We’re not just creating renewable fuel,” noted Dr. Kenji Tanaka, the project’s marine biologist. “We’re building a circular system that turns waste carbon into clean energy while conserving freshwater resources.”

Despite the excitement, challenges remain. Scaling to industrial production levels will require significant capital investment, and long-term engine compatibility studies are still underway. However, with several energy giants already expressing licensing interest, the technology may soon transition from pilot plants to global implementation. As nations intensify their pursuit of carbon-neutral energy solutions, this breakthrough offers a compelling—and timely—path forward.

The research team has made their methodology publicly available, though the enzyme formulation remains patented. They’ve called for international collaboration to adapt the technology to diverse climates and industrial contexts. As Dr. Vance concluded, “This isn’t just a laboratory curiosity. It’s a viable tool in humanity’s toolkit to combat climate change—and it’s ready for the real world.”

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025