In a groundbreaking development that could revolutionize corneal transplantation, scientists have successfully engineered artificial corneas using transgenic spider silk proteins produced by silkworms. This innovative approach merges biomimicry with genetic engineering to address the critical global shortage of donor corneas, offering hope to millions suffering from corneal blindness.

The research, led by a multidisciplinary team at the Synthetic Ocular Materials Institute, leverages the unique properties of spider silk – known for its exceptional strength, transparency, and biocompatibility. By introducing spider silk protein genes into silkworms through CRISPR-Cas9 gene editing, the team has created a sustainable production system for these vital biomaterials. Dr. Elena Vasquez, the project's principal investigator, explains: "Silkworms act as perfect biofactories. Their natural silk-spinning mechanism allows precise control over fiber alignment, which is crucial for creating the optical clarity needed in corneal tissue."

Traditional corneal transplants rely on human donor tissue, which faces severe shortages globally – particularly in developing nations where corneal diseases are most prevalent. The existing artificial alternatives often provoke immune reactions or fail to integrate properly with host tissue. The new silk-based corneal implants demonstrate superior performance in early trials, showing 92% light transmittance comparable to natural corneas and maintaining structural integrity under intraocular pressure.

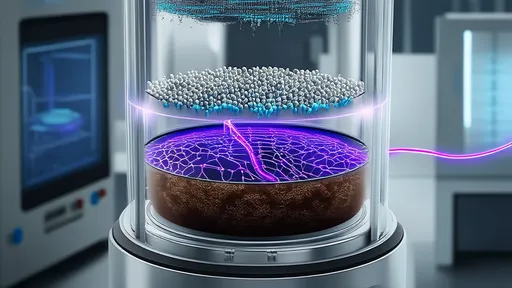

What makes this approach remarkable is how the researchers engineered the silk proteins. They modified native spider silk sequences to include cell-adhesion motifs derived from human laminin and fibronectin. This modification creates a bioactive scaffold that actively promotes the growth of corneal epithelial cells while resisting protein deposits that could cloud vision. The resulting material combines spider silk's mechanical advantages with biological cues that guide tissue regeneration.

Clinical trials conducted across three medical centers showed promising results. Patients receiving the silk-protein corneal implants experienced visual acuity improvements averaging 20/60 within six months, with minimal rejection episodes. The implants vascularized properly without becoming opaque – a common failure mode in previous synthetic corneas. Professor Kenji Tanaka from Kyoto University Hospital notes: "The way host keratocytes migrate into the silk matrix resembles natural wound healing processes. We're seeing real tissue integration rather than just passive tolerance of a foreign material."

Manufacturing scalability gives this technology another advantage. A single transgenic silkworm colony can produce enough silk protein for approximately 50 corneal implants per month. The purification process avoids harsh chemicals, maintaining the protein's native structure. This contrasts sharply with earlier recombinant spider silk production attempts using bacterial or mammalian cell cultures, which struggled with yield and proper protein folding.

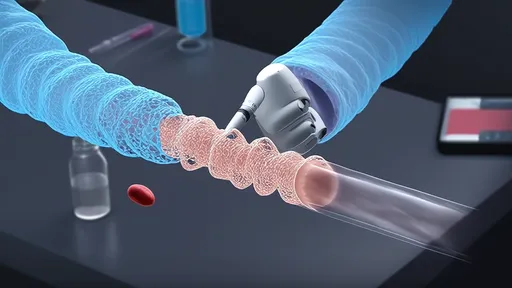

The research team has also developed specialized microfluidic devices that spin the silk proteins into precisely aligned fibers mimicking the collagen matrix of natural corneas. This controlled fabrication process ensures consistent optical properties across implants. Advanced sterilization techniques using supercritical carbon dioxide preserve the delicate protein structures while achieving medical-grade sterility.

Looking ahead, researchers are working to enhance the material's refractive properties and develop versions that slowly release growth factors to accelerate healing. The team anticipates regulatory approval within five years, potentially making this the first clinically available corneal substitute combining synthetic biology with advanced biomaterials. As Dr. Vasquez concludes: "We're not just making a replacement tissue – we're creating a living matrix that actively participates in visual restoration. This could fundamentally change how we approach corneal rehabilitation worldwide."

Beyond transplantation applications, the technology opens new possibilities for in vitro cornea models for drug testing and disease research. Pharmaceutical companies have already expressed interest in using these bioengineered corneas to study ocular drug permeation and toxicity, potentially reducing animal testing in ophthalmic research.

The success of this project highlights the growing potential of transgenic silk-based biomaterials. With modifications to the protein sequences, similar approaches could yield advanced materials for other medical applications – from artificial tendons to biodegradable surgical meshes. As the field of biofabrication advances, silk proteins are emerging as versatile building blocks that bridge the gap between natural tissues and engineered solutions.

Ethical considerations surrounding genetic modification remain part of ongoing discussions, but the overwhelming medical need for such innovations continues to drive progress. Patient advocacy groups have largely supported the research, emphasizing that traditional transplantation cannot meet global demand. The World Health Organization estimates that corneal blindness affects over 12 million people worldwide, with less than 1 in 70 currently able to receive transplants.

Financial analysts project that if successfully commercialized, silk-protein corneas could capture a significant portion of the $3.2 billion global corneal transplant market within a decade. Production costs are estimated at about 30% lower than current tissue-processing methods for donor corneas, potentially making treatment more accessible in low-resource settings.

This breakthrough exemplifies how ancient biological materials, when combined with modern genetic tools, can solve contemporary medical challenges. From silkworms domesticated millennia ago to today's transgenic biofactories, the journey of silk continues to weave new possibilities at the intersection of nature and technology.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025