In a groundbreaking advancement in micro-engineering, researchers have developed a novel method to manipulate and rotate microscopic objects using sound waves. This innovative technology, often referred to as an "acoustic tweezer micro-engine," leverages the principles of acoustic levitation to control tiny rotors with unprecedented precision. The implications of this breakthrough span across multiple fields, from biomedical engineering to micro-manufacturing, opening new avenues for non-contact manipulation at the smallest scales.

The core of this technology lies in the ability of sound waves to create pressure nodes that can trap and suspend particles in mid-air. By carefully tuning the frequency and phase of these waves, scientists can generate controlled rotational forces on microscopic objects. Unlike traditional methods that rely on physical contact or electromagnetic fields, this acoustic approach offers a gentler alternative that minimizes potential damage to delicate structures.

How Acoustic Levitation Powers Micro-Rotation

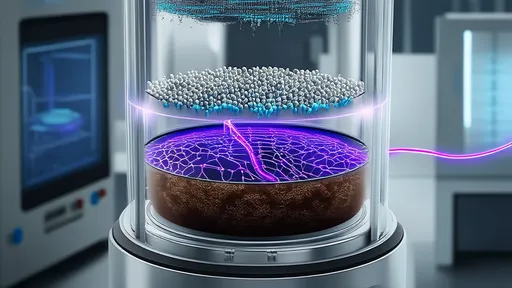

At the heart of the acoustic micro-engine is a sophisticated arrangement of ultrasonic transducers that generate standing waves in a carefully designed chamber. When microscopic rotors are introduced into this acoustic field, they naturally migrate to the pressure nodes where the forces balance out. What makes this system particularly remarkable is the ability to create dynamic pressure fields that change over time, effectively pushing the rotor blades in a specific direction to induce rotation.

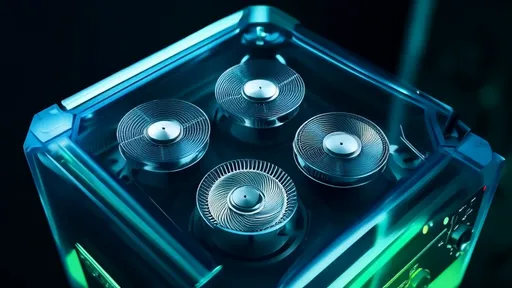

The precision of this method allows researchers to control not just the speed of rotation but also the direction, with the ability to switch rotation clockwise or counter-clockwise almost instantaneously. This level of control is achieved through real-time adjustments to the phase differences between multiple ultrasonic sources, creating what amounts to an invisible, sound-based gear system operating at frequencies beyond human hearing.

Potential Applications Across Industries

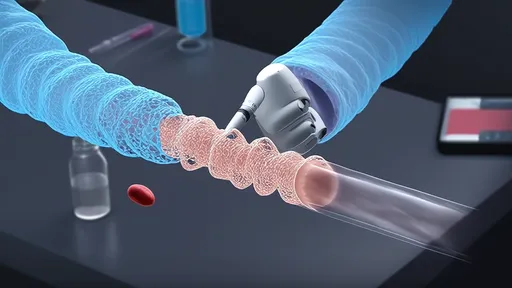

In biomedical engineering, this technology promises revolutionary approaches to handling sensitive biological samples. The non-contact nature of acoustic manipulation means cells or delicate microstructures can be rotated and examined from all angles without risk of contamination or mechanical damage. Researchers envision applications ranging from single-cell analysis to the assembly of complex tissue structures for regenerative medicine.

The micro-manufacturing sector stands to benefit equally from this advancement. Current methods for assembling micro-electromechanical systems (MEMS) often struggle with the challenges of handling and positioning tiny components. Acoustic micro-engines could provide a solution by enabling precise orientation and movement of parts during assembly processes, potentially revolutionizing the production of everything from micro-sensors to optical devices.

Overcoming Technical Challenges

Developing this technology hasn't been without its hurdles. One significant challenge has been maintaining stable rotation at micro-scales where viscous forces from the surrounding air or fluid can dominate the dynamics. The research team addressed this by optimizing the shape of the microscopic rotors and carefully controlling the acoustic field parameters to ensure consistent performance across different environmental conditions.

Another obstacle involved scaling the technology for practical applications. Early prototypes could only manipulate single particles in highly controlled laboratory settings. Recent advancements have expanded this capability to handle multiple rotors simultaneously, each with independent control, paving the way for more complex micro-mechanical systems powered entirely by sound.

The Future of Acoustic Micro-Engines

As the technology matures, researchers anticipate even more sophisticated applications. One promising direction involves integrating these acoustic systems with microfluidic devices, creating lab-on-a-chip platforms where sound waves handle both the movement of fluids and the manipulation of particles within them. Such integrated systems could dramatically simplify complex diagnostic procedures or chemical synthesis processes.

Another exciting frontier is the development of acoustic micro-robotics. By combining precise acoustic control with smart materials, scientists envision creating microscopic machines that can perform tasks in environments inaccessible to conventional robots, from inside human blood vessels to extreme environments where traditional actuators would fail.

The acoustic tweezer micro-engine represents more than just a technical achievement—it demonstrates how fundamental physics principles can be harnessed to solve practical engineering challenges at microscopic scales. As research continues to refine and expand this technology, we may soon see sound-powered microsystems becoming commonplace in laboratories and industries worldwide, quietly revolutionizing how we interact with the microscopic world.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025