The quest for more efficient renewable energy solutions has led engineers to an unlikely muse: the shark. Known for their effortless glide through water, sharks possess a unique skin texture that reduces drag and enhances speed. This biological marvel has now inspired a breakthrough in wind turbine design, where microscopic grooves mimicking shark skin are being applied to turbine blades. The results? A measurable increase in energy output with minimal structural modifications.

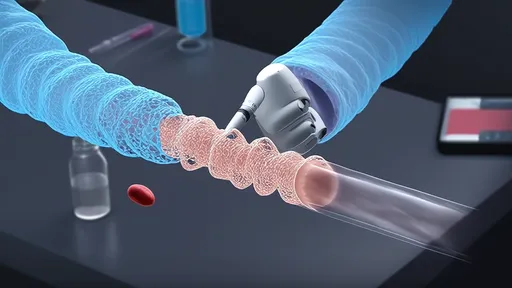

Traditional wind turbines face a persistent challenge – aerodynamic drag. As blades slice through the air, turbulence forms along their surfaces, creating resistance that diminishes efficiency. For decades, researchers sought solutions in smoother surfaces, unaware that nature had already perfected a better approach. The shark's dermal denticles (tooth-like scales) create controlled micro-vortices that actually streamline flow rather than disrupt it. When translated into turbine blade technology, these riblet patterns demonstrate surprising benefits.

Field tests across multiple wind farms reveal consistent performance improvements. Turbines equipped with biomimetic grooved blades show 5-8% greater energy capture compared to conventional designs under identical wind conditions. This gain stems from two synergistic effects: the grooves delay airflow separation (maintaining lift longer along the blade) and reduce surface friction (allowing blades to rotate more freely). For a 2MW turbine, this translates to an additional 400,000 kWh annually – enough to power 40 extra homes without requiring larger blades or stronger winds.

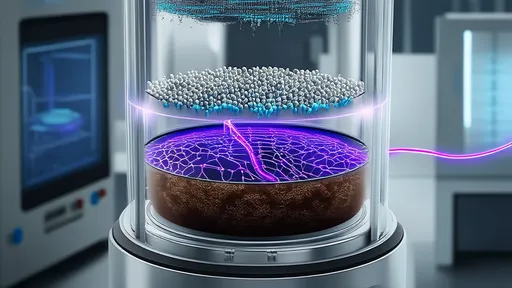

The manufacturing process involves either machining microscopic channels directly into blade coatings or applying adhesive films patterned with optimized riblet geometries. Companies like PowerCoat and BioFlow Turbine Systems have developed proprietary methods to ensure these delicate structures withstand years of weather exposure. "It's not just about sticking grooves anywhere," explains Dr. Elena Voss, lead engineer at BioFlow. "The alignment, depth, and spacing must follow precise mathematical models matching local wind patterns."

Beyond new installations, the technology offers a compelling retrofit opportunity. Existing turbines can be upgraded with groove-applied films during routine maintenance, extending facility lifespans without costly blade replacements. German energy firm Windkraft GmbH reported a 6.2% output boost across 47 retrofitted turbines in the North Sea, achieving ROI within 14 months. Such data is driving rapid adoption, particularly in offshore wind where consistent breezes maximize the drag-reduction effect.

Environmental benefits compound the economic case. By squeezing more power from existing turbines, the technology reduces the need for additional units that would otherwise occupy land and require raw materials. Marine biologists also note an unexpected advantage: grooved blades appear less attractive to certain bird species, potentially lowering collision risks. While more study is needed, early radar tracking shows altered flight patterns around modified turbines.

Challenges remain in mass implementation. Precision application demands specialized equipment and trained technicians, currently limiting deployment to larger wind farms. There's also debate around optimal groove designs – some favor triangular profiles while others advocate for scalloped patterns. NASA's ongoing wind tunnel comparisons may soon provide definitive answers, building on their original research into riblet coatings for aircraft.

As climate targets grow more ambitious, such incremental efficiency gains become crucial. "Nobody will build their way to net-zero with current turbine productivity," remarks MIT's Professor Carl Reese. "Technologies like biomimetic grooves represent the next frontier – working smarter with what we have." With several patents filed and pilot programs expanding globally, the shark's evolutionary advantage may soon breathe new life into wind energy worldwide.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025